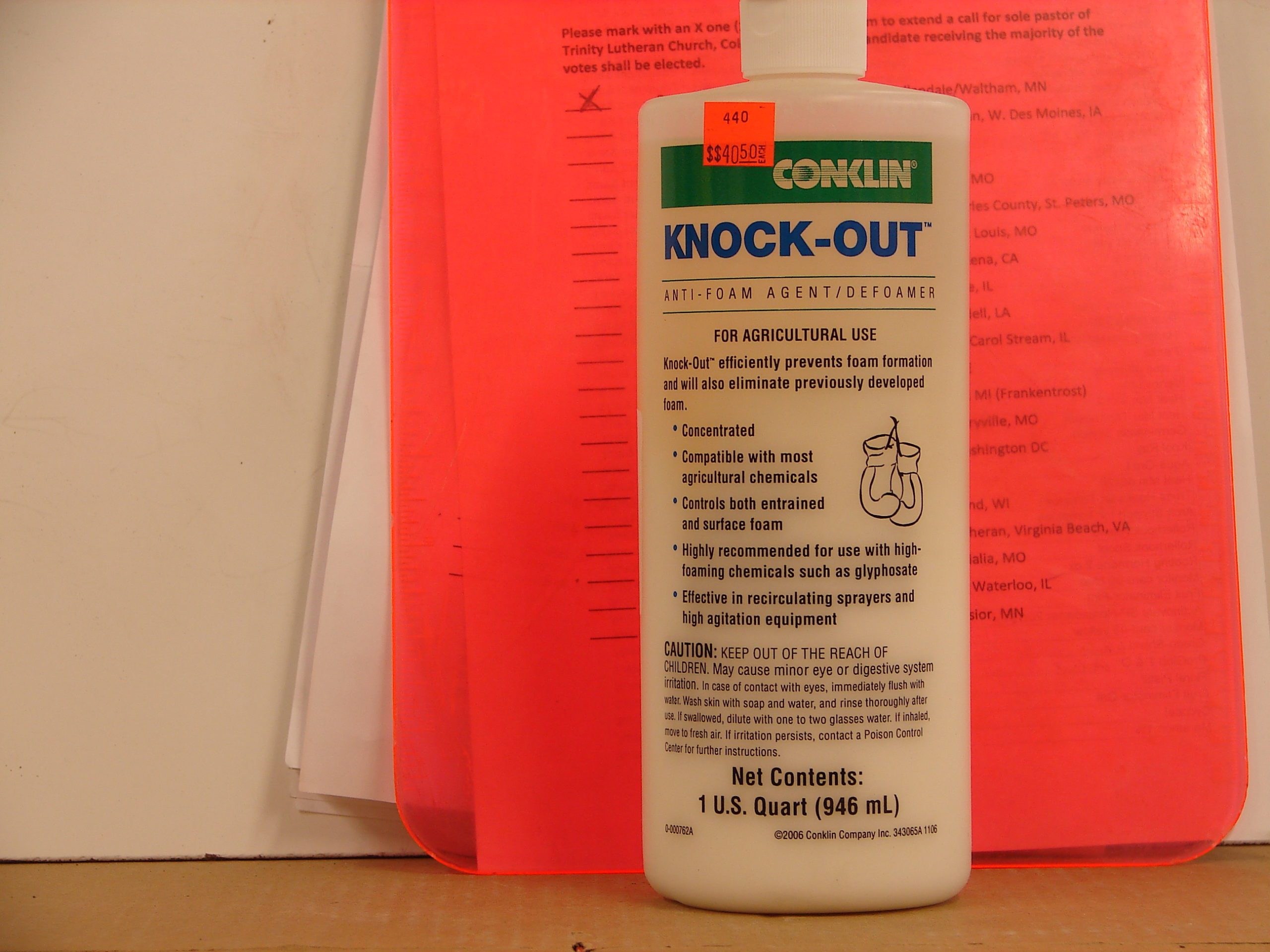

Anti-Foam Control Solutions-- Reliable Solutions for Foam Reduction in Production

Trick Benefits of Executing Anti-Foam Control Solutions in Manufacturing Procedures

The execution of anti-foam control solutions in manufacturing processes provides a critical advantage that advantages mindful factor to consider. By dealing with problems connected to foam development, manufacturers can considerably improve manufacturing performance, improve product quality, and reduce operational expenses.

Enhanced Production Effectiveness

In producing processes, foam can significantly prevent production effectiveness by blocking equipment and interrupting process. The existence of foam often brings about devices breakdowns, calling for unscheduled upkeep and downtime that can severely affect production timelines. When bubbles create in liquids, they can create clogs in pumps, pipes, and various other important parts, leading to irregular product circulation and increased functional prices.

Implementing anti-foam control remedies is important for minimizing these problems - Anti-Foam Control Solutions. These options work by minimizing foam formation, making sure smoother procedures and decreasing the danger of machinery clog. By maintaining ideal fluid dynamics, manufacturers can boost throughput and reduce the frequency of equipment maintenance, eventually enhancing the overall efficiency of the production line

Furthermore, with minimized downtime, staff members can concentrate on various other crucial tasks, further enhancing processes. Using anti-foam agents not just addresses immediate manufacturing difficulties yet additionally fosters a more stable manufacturing environment. In turn, this adds to better resource administration and cost financial savings, reinforcing the relevance of purchasing reliable foam control approaches as a way to boost production effectiveness in producing setups.

Enhanced Item High Quality

Foam in producing procedures can endanger item top quality, leading to inconsistent results and customer dissatisfaction. The presence of foam can hinder the correct combination of products, causing flaws such as air pockets, unequal textures, or instability in final product. These defects not only impact the aesthetic charm yet can additionally influence the functional performance of the item.

Carrying out anti-foam control services effectively mitigates foam formation, guaranteeing an uniform item uniformity. By keeping the desired thickness and security of materials during processing, manufacturers can accomplish better results. This improvement in product quality equates into boosted reliability and complete satisfaction for end-users, fostering brand commitment and a solid market presence.

In addition, advanced anti-foam agents can be customized to specific producing processes, guaranteeing optimum performance without adversely affecting various other properties of the formulation. By integrating these solutions, makers can promote rigid high quality requirements while reducing the threat of product remembers or remodel, which are harmful and typically expensive to track record.

Cost Reduction Techniques

Carrying out efficient anti-foam control options not only enhances item high quality however likewise substantially adds to cost decrease approaches in production. By decreasing foam development, suppliers can minimize waste related to overflows and spills, which frequently result in product loss and raised functional expenses. This not just maintains basic materials however likewise enhances production processes, inevitably causing higher check it out efficiency.

Moreover, consistent foam control can enhance process stability, minimizing the chance of production downtimes caused by foam-related interruptions - Anti-Foam Control Solutions. By accomplishing smoother operations, producers can maximize their throughput, leading to boosted overall performance and success

On top of that, with lowered requirement for extra additives and lower energy consumption during manufacturing, business can even more understand significant savings. Spending in anti-foam control services stands out as a tactical technique to achieving extensive cost reductions in manufacturing environments.

Boosted Equipment Longevity

Reliable anti-foam control services play an important role in extending the long life of production devices. Extreme foam buildup in production processes can result in considerable damage on machinery, in addition to practical inefficiencies. When foam builds up, it can block circulation courses, causing pumps and various other devices to work go right here more challenging than required, which increases mechanical deterioration.

Furthermore, foaming can lead to rust, especially in liquid systems where foam traps chemical representatives that may be detrimental to devices surfaces. By implementing anti-foam control remedies, makers can reduce these dangers, making sure smoother operations and decreasing the regularity of repair and maintenance.

Better Compliance and Safety

Enhanced conformity and safety standards in making procedures are dramatically affected by the integration of anti-foam control services. These solutions effectively minimize the threats related to foam formation, which can bring about unsafe problems, such as spills or devices malfunctions. By controlling foam, suppliers can keep a much safer working atmosphere, decreasing the likelihood of crashes that might result in injuries or damages to devices.

In addition, governing conformity is essential in the manufacturing sector. Anti-foam representatives play an essential function in adhering to sector requirements and environmental laws. By decreasing foam-related discharges and effluents, companies can demonstrate their dedication to ecological stewardship while avoiding possible penalties and legal effects.

Furthermore, efficient foam control boosts process efficiency, enabling regular product top quality and minimized waste. This not just satisfies client expectations however also lines up with the most effective methods described by governing bodies.

Conclusion

The implementation of anti-foam control solutions in making processes returns substantial advantages, consisting of boosted production effectiveness, improved product top quality, and substantial expense decreases. These remedies not only lessen foam development but likewise add to boosted equipment durability and conformity with safety and security and environmental guidelines. By addressing these essential areas, makers can achieve greater functional quality and success, eventually cultivating an extra sustainable and efficient production atmosphere.

In turn, this adds to far better source management and expense financial savings, enhancing the relevance of investing in effective foam control techniques as a way to boost manufacturing performance in making settings.

Carrying out anti-foam control options successfully mitigates foam formation, guaranteeing an uniform product uniformity. These services properly minimize the threats linked with foam development, which can lead to unsafe problems, such as spills or tools breakdowns. By regulating foam, makers can maintain a much safer working atmosphere, minimizing the probability of mishaps that may result in injuries or damage to devices.

These remedies not just lessen foam formation but also add to boosted equipment long life and conformity with security and environmental regulations. Anti-Foam Control Solutions.